|

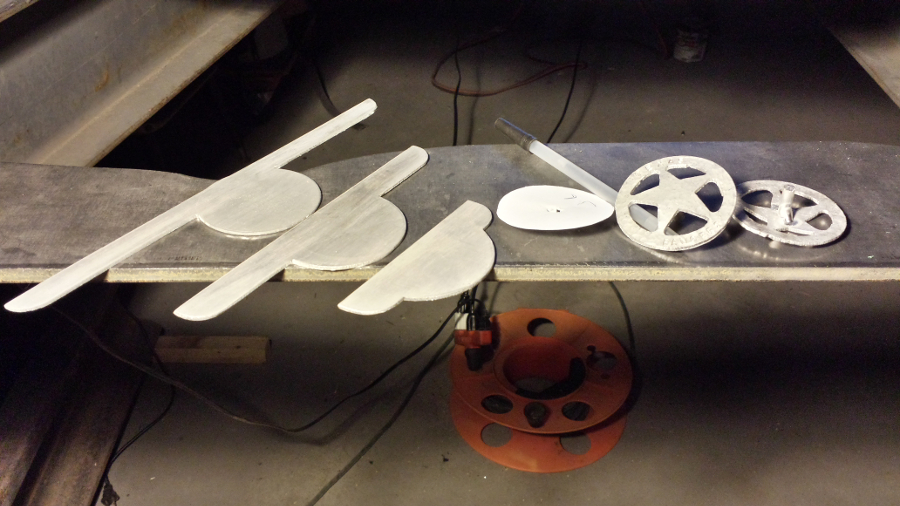

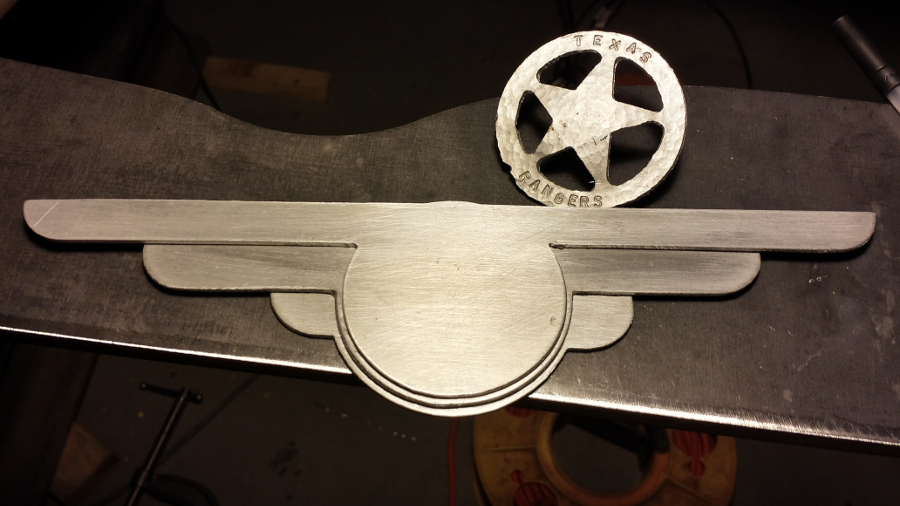

I have had this idea to liberate my Grandfather's (on my dad's side) walker he used until He was 99 years old. Here my Grandfather Louie, and my Aunt are pictured in 1920's in front of the house they moved by horses over two days, two miles to another location across the street where the Navajo Hogan was later built. I remember we use to go the nursing home to see Louie, my father made him walk down the hall every day. My Grandfather had gone to the hospital a few years earlier, and when he was in bed for a week with his knees bent, no one though much of it. As it turned out his hamstrings contracted and he could no longer straighten his legs. So my father had him exercise to increase the range of movement in his legs. Anyway, I ran across his walker in storage some 34 years later, and decided to put new energy to an object most people think represents a handicap. I saw a TED talk about an English woman Sue Austin who opened my eyes to how enabling wheel chairs are to those who can not get around without them. She would go diving in the ocean with her wheel chair, to compare SCUBA to the wheel chair. Humans are handicap to stay under water for extended lengths of time without SCUBA equipment, but it has a stigma of being adventurous, unlike the wheel chair, or a walker. I chose to use a reference to a powerful hero from Texas. The synonym of the name Walker here helps my cause to shed a new light on an object society sees as sad or a burden on a person, whereas it liberates them to get out in the world. the streamline back drop; to speak of the time the walker was made. Pictured below the badge assembled prior to patina work. presenting: Walker Texas Rangers

0 Comments

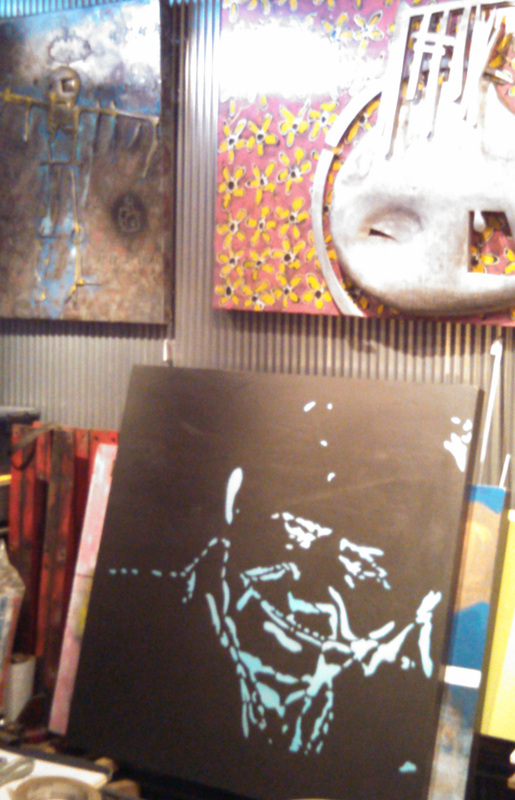

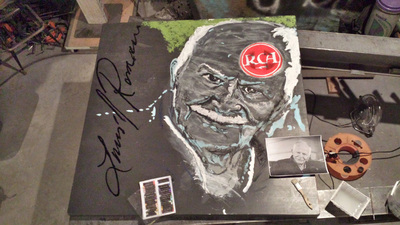

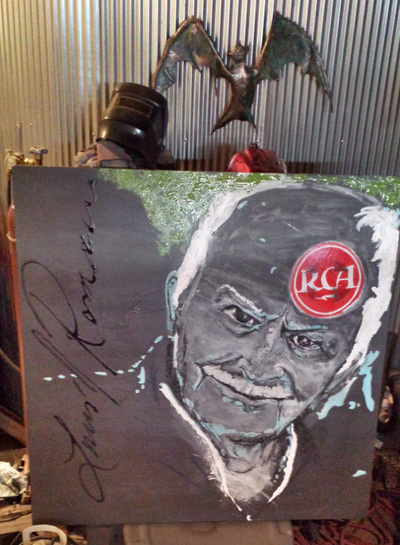

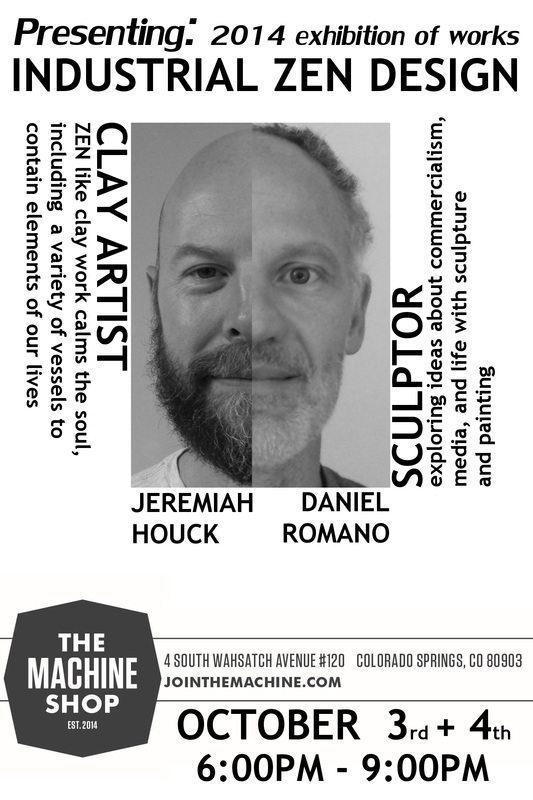

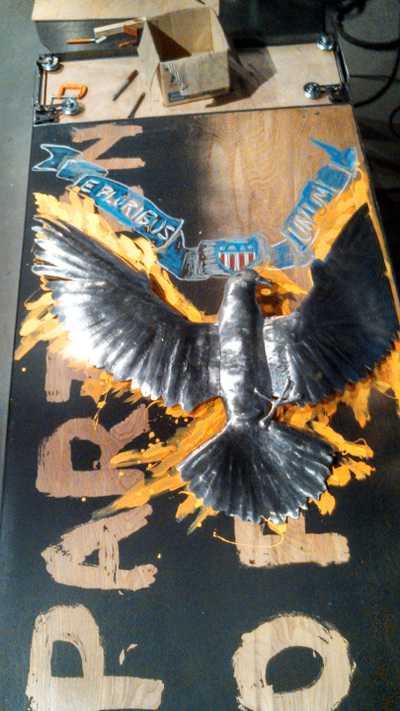

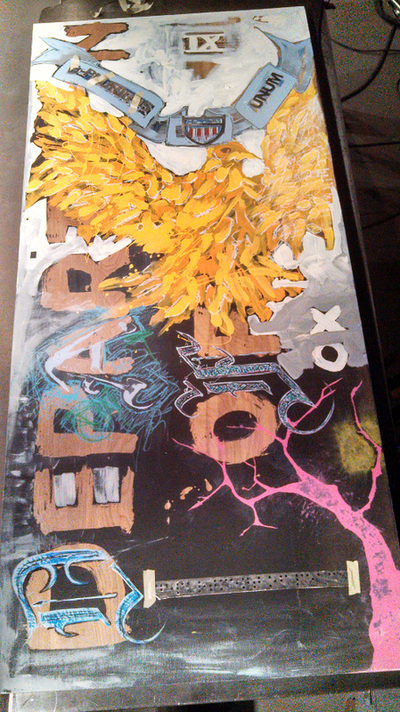

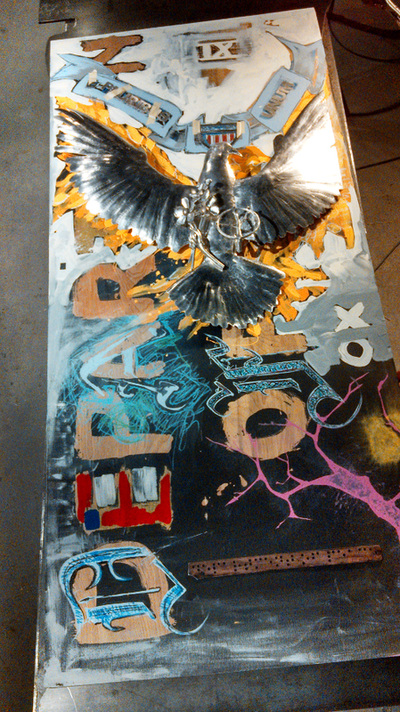

This is a study of one of the last images of my father from 2003 taken by Jennifer Horsman. I started the panel in early 2014; when the initial work look more like Marvels 'Thing' from the Fantastic four, I painted over the panel to try another direction. Lost for direction from May, just yesterday I had an idea to start work on the panel. As you may have guessed from reading about my past, the television business has always been a prominent association with my father, and represents a part of what he introduced to me at a young age; electronics, construction, art, he was never afraid to do anything he tried. Digging old style wells, running a horse pulled scoop under a house (pulled by a military jeep), laying brick (something even today I have yet found a love for.) Anyway, I have placed images that represent his passion for building and making things work. Gallery: select images belowAfter the blue was added to he jacket, I promptly removed it with lacquer thinner before it started to set, but now as I look back it was no where as overpowering as it seemed. There is still some blue remaining. Presently the work is H 48" W 48" D 3" Forming the sheet metal raised sides to the characters, then tack welded. Completed characters ready for grinding, then patina work. Character height 10" Gallery: select images belowCharacters mounted to panel, after patina work, Gallery: select images belowform more information on the show here is a link to The Machine Shop The Machine Shop: 4 South Wahsatch COS 80903 http://www.jointhemachine.com/ Facebook links: Machine Shop sign install show image Friday OCT 3 Friday OCT 3 show image Saturday OCT 4 Gallery: select images belowDept of Peace an installation in part inspired by James Turell, and his sky space work. The plaster ceiling of the room was removed and re-framed to resemble saw tooth waves, lighting was installed behind each of the two waves to create a gradient light to fill the room. The door was to be a moving painting, with sculpted relief in aluminium. The subject for the moving panel is a variation of the United States Seal , but the eagle and its elements are replaced with a dove, flowers and a ring, which encircles the doves foot, a sign of peace. The rail was designed after steel bar joist, incorporating the roman numerals of the date built. composed of stainless solid square bar. Gallery: select images below building the panelGallery: select images below details of the panel and lightingThis work is designed around a carved brick monolith which is Celtic in style. The monolith was carved by a friend Tom Durham of Pueblo Colorado. The element to be mounted a top the monolith is a version of the power symbol; a favorite of my sons drawings for the last two years. This is tribute to his imagination, and ideas.  forming the 11 gauge material to the inner and outer circumference of the form. closer fit final adjustments next before tack welding TIG welding of inner and outer circumference complete, The Power Symbol placed on the monolith prior to cleaning the masonry work. The finish work on welds were only slightly sanded, to leave a carved appearance as this piece is to oxidize naturally, having the material deposited in the brick work below as time ages the entire piece.

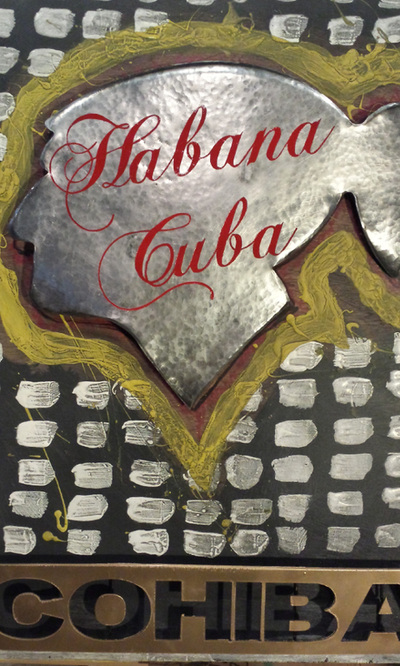

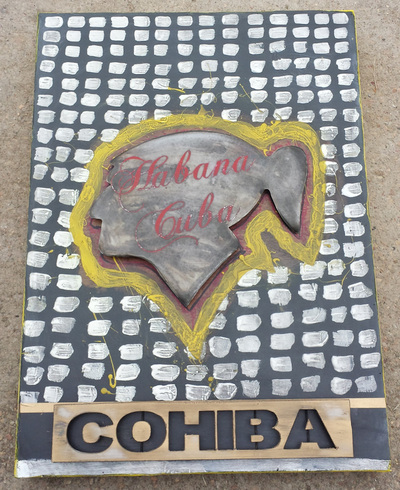

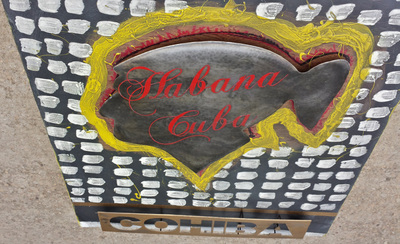

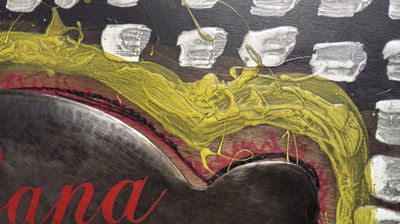

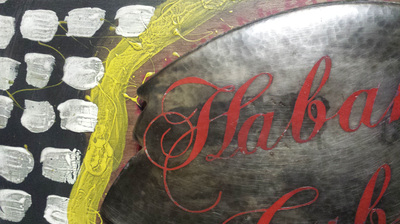

Cohiba is a new work from the past two days, it is simply an idea based on coveted brands. This piece has a rough feel from a country rich with character and a intriguing history. Planishing is used to slightly form the center element, also enriching its surface texture. formed steel, on painted wood panel W27" H37" D4.5" Gallery: select image belowFire Chief

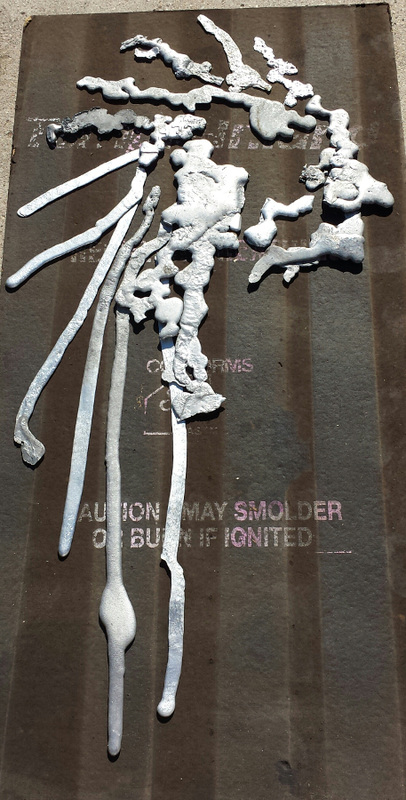

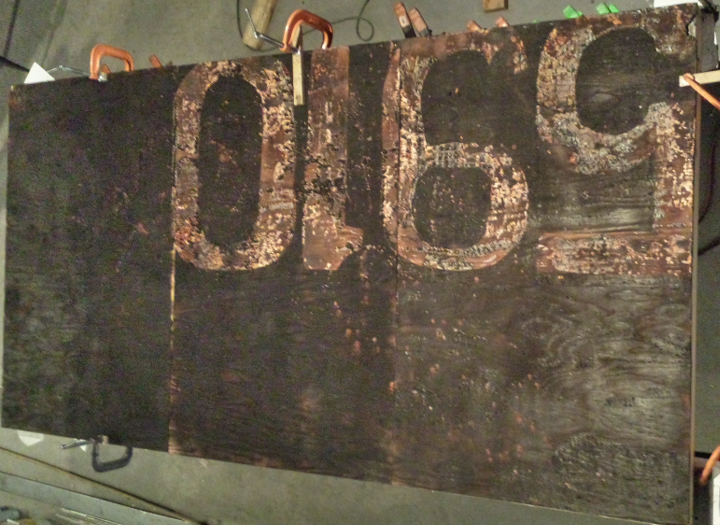

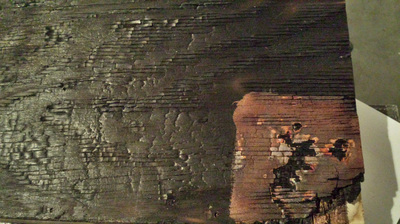

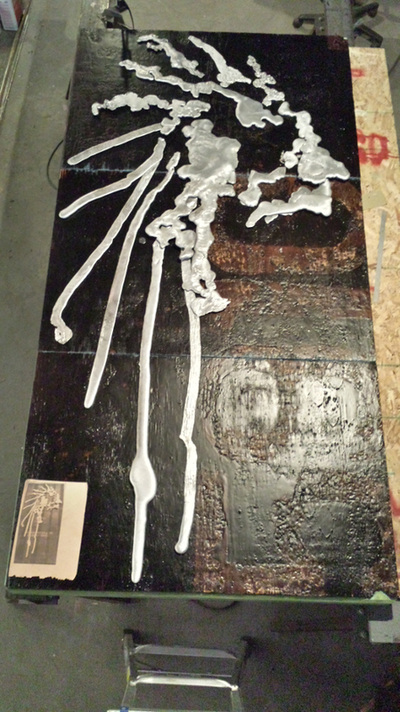

The Celotex panel led to the idea of incorporating charred wood Shou Sugi Ban 焼杉板 as the background panel, below are some samples of the charred wood with metal characters, which led me to use copper paste prior to charring. Other samples with Aluminum samples from the clients selection. Gallery: select images belowbuilding the panelGallery: select images belowGallery of close up images of the charred panel, the copper reminds me of Raku, the delicate nature of the surface reminds me of paint work on copper brass and bronze. Care must be taken to coat the surface to bond the charred surface to the remaining wood surface. Gallery: select images belowAttching the Aluminium elements to the charred wood panel. The thickness of the pieces range from 1/16" to 3/4". Sections with thicknesses of 3/8" and more can be drilled and taped, otherwise threaded aluminium rods must be TIG welded to the back surface. Gallery: select image belowEpilogue: After attaching all threaded studs to the fire cast aluminium pieces the mounting process of arranging the elements on the completed panel. Mounting points are then transferred and drilled, for each piece, some are layered others are on their own. A nice analogy from the pattern of the completed piece is a representation of the Black Forrest Fire how the fire spread out in different directions, leaving places untouched by its destruction. Completed piece dimensions: W 48" H 96" D 6.5" Sept 2014

|

Daniel RomanoArtist/Designer/Sculptor Archives

September 2022

CategoriesCopyright © 2022

All Rights Reserved ROMANODANIEL |

RSS Feed

RSS Feed