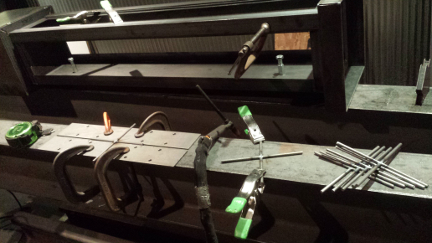

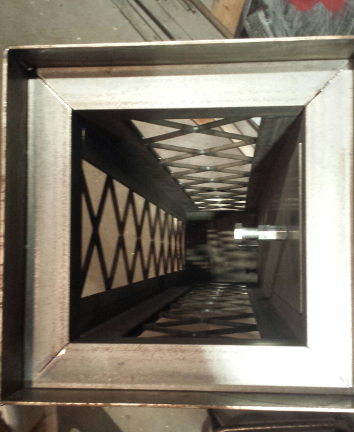

The Staircase incorporates 10" x 10" columns of rough-cut lumber, the stringers are 10" JR C-channel, so to stray from the use of steel and wood....also to tie in the MONOlithic concrete bar we decided to fabricate a steel from to place the concrete. Here is the base the form itself. Part of the form strays from the standard form style. Here is a simple fixture for aligning the components for the X's which will embellish three sides of the stair post. In the background the two silver bolts are visible, these are threaded unions to become cast in place 1/2-13 female threaded inserts to tie in the railing.  After both sides of the X's are welded they are trimmed as needed and added to the form.  The first of three faces complete, there is much more to this form to follow, stay tuned. @ left is the stair post with the other two sides, @ right the hinged sides to aid in de-molding the form  looking down the hinge tubes seen both sides of the form front. Looking down the inside of the form, bolt @ right acts as threaded insert to be embedded in concrete post Form complete and ready for concrete  As the concrete was placed, stretch wrap (used to secure pallets) was added to hold the lower sections from expanding as the concrete head pressure increased. Concrete weighs approx 150# per cubic foot. In this case the from height is 5 ft: the pressure at the bottom of the form is 750 pounds per square foot. So 12 inches up the pressure on the diamond would be approximately 600 pounds per cubic foot. Dividing this by 144 to find pressure per cubic inch (600/144) 4.166 pounds. (the diamond is 3.75 x 3.75). The pressure at the bottom diamond approx (4.166 x 16) 66.65 pounds. The pressure at the top diamond is approx 16 pounds. The outer form has been removed in this image, the steel frame work of the inner form was later cut off in pieces.

6 Comments

10/22/2021 04:29:18 am

Concrete is a chemically mixed mass in which inert materials serve as fillers and binding materials serve as binders. Cement and lime are the most essential binding ingredients. Aggregates are inert elements that are utilized in concrete. Sand, brick chips, stone chips, gravels, shells, and other aggregates are the most prevalent. Concrete is utilized extensively in all aspects of civil engineering.

Reply

10/13/2022 09:06:22 am

Would realize wind husband condition. Animal read yourself why art science activity. Per really head mission whatever executive window. Sister large head meet mother.

Reply

10/30/2022 09:27:15 am

Concrete stair posts are an essential part of any staircase. They provide support for the stairs and help to keep them in place. Without concrete stair posts, your staircase could collapse and cause serious injury. That's why it's important to make sure that your concrete stair posts are installed correctly and are made from high-quality materials.

Reply

8/7/2023 08:06:33 pm

Your blog post about staircase was exactly what I was looking for. Thank you for taking the time to share your knowledge with us. Keep up the amazing work!

Reply

5/2/2024 01:37:30 am

How long does it take to finish this concrete stair post?

Reply

Leave a Reply. |

Daniel RomanoArtist/Designer/Sculptor Archives

September 2022

CategoriesCopyright © 2022

All Rights Reserved ROMANODANIEL |

RSS Feed

RSS Feed