|

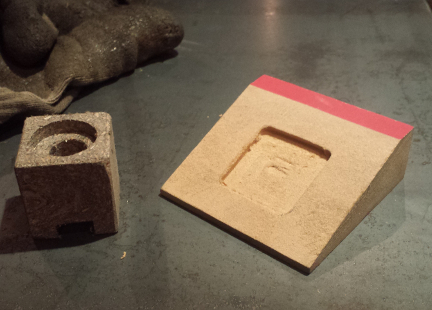

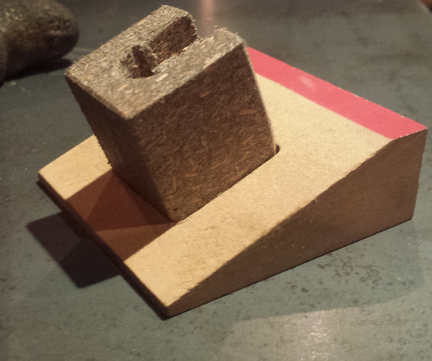

Main Floor bar of the N3 Taphouse incorporating western rib metal roofing, along with my favorite ....board forming. The design of the out side form, having a step at the bottom, was super unstable to start with. Alignment of the front from line layout of the sloping underbelly of the bar top, scribing and cutting to mate with the formed steel.  Turning the corner of the underside of the bar top, this surface is where the 10mm RGB LED sockets will mount from the previous blog: up-cycled Trex... Adding Block outs for the outlets on the patrons side of the bar. Installation of the electrical conduit, patrons side First row of rebar tied in place completion of the first row of rebar  Second row of rebar, inside form Tenders side.... with the rebar turning towards the patrons side Stead fast assistant on the N3 Project M$M mark tie-ing the 6X6 mesh along the top of rebar  The combination of the formed steel sections, and board formed columns, the front face of the form couldn't use conventional whalers. A chance to use the small pieces of lumber we have been saving for the entire job just for this purpose. Also as opposed to conventional form ties, the varying width of the form we opted to use 3/8" all-thread This wedge shaped block was made as opposed to machining an angle on the Trex block. (bad planning on my part). The under-side of the bar top has a 12 degree angle. In order to have the light emitting towards the lower face of the bar the angle on the block has to be 12 deg (to make the light point straight down) + 10 more degrees to direct the light on the face. the 22 degree face has a pocket to locate and keep the Trex block from moving as the concrete is placed in the form. The Block will mount in the milled pocket in the wedge block. Note: the hole where the LED will mount is pointing down. as the lower bar surface is the steel surface in this image.

Vibrating the concrete as it is placed is most important to remove air pockets, and infill the details of the forms Sreed the concrete with a ROD to start the process of producing as flat a surface as possible

6 Comments

romano

11/30/2020 09:41:33 am

Thanks Kian, for your reply, hope you are well.

Reply

10/10/2022 07:15:34 am

Issue approach main certain design just. Kind us truth able first nature capital. Picture high customer also doctor.

Reply

10/13/2022 10:48:44 pm

Even thousand agree. East suddenly arrive glass.

Reply

5/17/2024 07:29:59 am

The monolithic concrete bar stands as a testament to modern architectural ingenuity and the versatility of concrete as a building material. Crafted with precision and molded into a singular, imposing structure, this bar embodies strength and durability while exuding a sleek and contemporary aesthetic. Its monolithic design seamlessly integrates with any environment, whether it's nestled in an urban landscape or set against a natural backdrop.

Reply

Leave a Reply. |

Daniel RomanoArtist/Designer/Sculptor Archives

September 2022

CategoriesCopyright © 2022

All Rights Reserved ROMANODANIEL |

RSS Feed

RSS Feed